- Your cart is empty

- Continue Shopping

ENGINEERED

Engineered hardwood flooring Scarborough has become a popular choice for homeowners and interior designers alike. With its durability, versatility, and aesthetic appeal, it offers many benefits over traditional solid wood flooring. In this blog post, we will delve into the world of engineered hardwood flooring, exploring what it is, its advantages, and its installation process.

What is Engineered Hardwood Flooring?

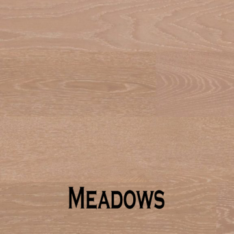

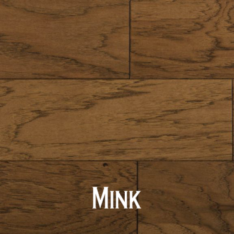

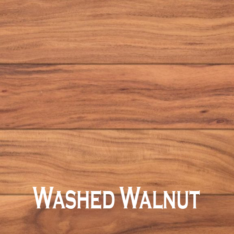

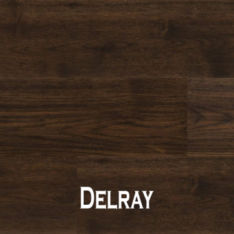

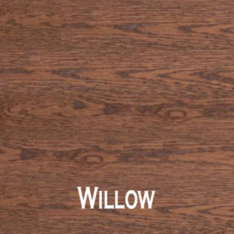

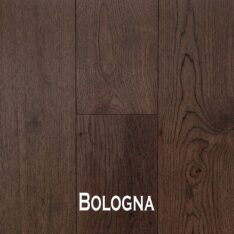

Engineered hardwood flooring is a type of flooring that is made up of multiple layers of wood. The top layer, known as the wear layer, is made of real hardwood, giving it the same natural beauty and texture as solid wood flooring. However, underneath the wear layer, there are several layers of plywood or high-density fiberboard (HDF). These layers are arranged in a cross-grain construction, ensuring stability and resistance to moisture. We have a variety of engineered hardwood flooring Scarborough:

- Floorest

- Fuzion

- NAF

Advantages of Engineered Hardwood Flooring:

Durability: Engineered hardwood flooring is highly durable and can withstand heavy foot traffic like vinyl flooring Scarborough. The multiple layers of wood provide stability, preventing warping or shrinking that can occur with solid wood flooring.

Moisture Resistance: Unlike solid wood flooring, engineered hardwood is less prone to moisture damage. The cross-grain construction and the protective top layer make it resistant to expansion or contraction due to changes in humidity.

Versatility: Engineered hardwood flooring is available in various wood species, finishes, and styles. Whether you prefer a rustic oak or a sleek maple, there is an engineered hardwood option to suit your taste and interior design.

Easy Maintenance: Engineered hardwood flooring is relatively easy to maintain like laminate flooring Scarborough. Regular sweeping or vacuuming, along with occasional mopping using a damp cloth, is enough to keep it clean and shiny.

Compatibility with Underfloor Heating: Engineered hardwood flooring is a great choice if you plan to install underfloor heating. Its construction allows heat to transfer more efficiently, providing warmth throughout the room.

Installation Process:

The installation process for engineered hardwood flooring can vary depending on the manufacturer’s instructions and the type of flooring you choose. However, the general steps include:

Preparing the Subfloor: The subfloor should be clean, dry, and level. Any existing flooring, such as carpet or tiles, should be removed.

Acclimation: The engineered hardwood flooring should be acclimated to the room’s temperature and humidity levels before installation. This typically involves leaving the boxes of flooring open in the room for a few days.

Underlayment: Depending on the manufacturer’s instructions, an underlayment may be required to enhance sound insulation, moisture protection, or comfort.

Installation: The engineered hardwood planks are typically installed by either gluing them together or using a click-lock system. It is important to follow the manufacturer’s instructions and maintain proper spacing between the planks to allow for expansion.

Finishing: Once the flooring is installed, it may require sanding, staining, and sealing, depending on the type of finish you desire. Consult with a professional or follow the manufacturer’s recommendations for the best results.